$19.00

Whether you’re a seasoned cyclist upgrading your ride or a beginner piecing together your first bike, understanding the intricacies of bicycle components is key to a smooth and safe experience. One often-overlooked yet crucial part is the fork dropout. In this comprehensive guide, we’ll dive deep into what makes the fork dropout – no 1 in terms of reliability and performance for modern bicycles. We’ll cover everything from basics to advanced tips, ensuring you have all the information needed to make informed decisions. By the end, you’ll know why selecting the right fork dropout can transform your cycling adventures.

At its core, a fork dropout is the slot or opening at the end of a bicycle’s front fork where the wheel axle secures into place. It’s essentially the connection point between your fork and the front wheel, allowing for easy attachment and removal while maintaining stability during rides. Without a properly functioning fork dropout, your wheel could wobble, leading to unsafe handling or even accidents.

Fork dropouts come in various designs, each tailored to different types of bikes and riding styles. For instance, on a mountain bike, the fork dropout needs to handle rough terrain and quick wheel changes, while on a road bike, it prioritizes aerodynamics and lightweight construction. The term “dropout” originates from how the wheel “drops out” of the slot when removed, a feature that’s been part of bicycle design for decades.

To visualize this, here’s a close-up view of a typical bicycle fork dropout in action:

As you can see, the dropout is a small but mighty component, often made from materials like steel, aluminum, or carbon fiber to balance strength and weight. In historical context, early bicycles used simple open slots, but advancements have led to more secure systems. According to cycling experts, the evolution of fork dropouts has significantly improved bike safety and efficiency over the years.

Why should you care about fork dropouts? They play a pivotal role in your bike’s overall performance. A well-designed fork dropout ensures precise wheel alignment, which affects steering accuracy, braking efficiency, and even how power is transferred from your pedals to the road or trail. Misaligned dropouts can cause uneven tire wear, vibrations, or worse, structural failure under stress.

For enthusiasts pursuing the fork dropout – no 1 in performance, consider how it integrates with other parts like the axle and hub. Quick-release systems, for example, allow for fast wheel swaps during races or repairs, while thru-axle designs provide superior stiffness for high-speed descents. Studies from bicycle engineering forums highlight that upgrading to a high-quality fork dropout can reduce flex by up to 20%, enhancing control on challenging terrains.

Moreover, fork dropouts influence compatibility with accessories. If you’re adding fenders, racks, or even converting to an electric assist system, the dropout design must accommodate these without compromising integrity. In urban commuting, where quick fixes are essential, a reliable fork dropout – no 1 priority becomes evident in preventing downtime.

Bicycle fork dropouts aren’t one-size-fits-all. There are several types, each with unique advantages. Let’s break them down to help you identify the fork dropout – no 1 for your needs.

Vertical dropouts are the traditional choice, featuring a downward-facing slot where the axle bolts or clamps in place. They’re common on road and hybrid bikes because they allow for straightforward wheel installation without needing to adjust chain tension. However, they require precise alignment to avoid wheel slippage.

Pros:

Cons:

Horizontal dropouts, often seen on fixed-gear or single-speed bikes, run parallel to the ground. This design allows for chain tension adjustments by sliding the wheel forward or backward. They’re ideal for track cycling or custom builds where versatility is key.

Pros:

Cons:

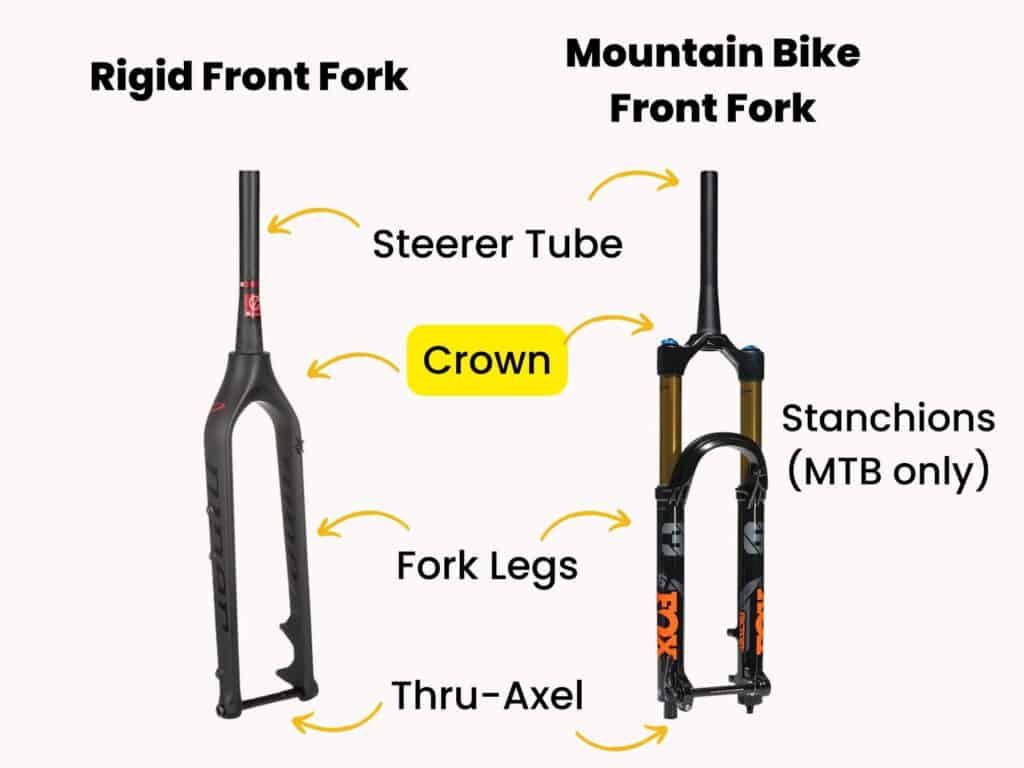

Here’s a diagram illustrating the differences between rigid and suspension fork types, which often incorporate various dropout styles:

A hybrid of vertical and horizontal, semi-vertical dropouts offer a slight angle for better adjustability. They’re popular in touring bikes, providing a balance between ease of use and customization.

Pros:

Cons:

Considered by many as the fork dropout – no 1 for modern mountain and gravel bikes, thru-axle dropouts use a threaded axle that passes through the hub and screws into the dropout. This creates a rigid connection, reducing flex and improving handling on technical trails.

Pros:

Cons:

Thru-axle systems have become standard in competitive cycling, with brands like Fox and RockShox integrating them into high-end forks. For off-road enthusiasts, this type often emerges as the top pick due to its durability.

Specialized dropouts include hooded or plug styles for custom frames, often used in framebuilding. These are precision-engineered for specific axle sizes, like 12mm or 15mm, and are favored in high-performance setups.

To compare these types side by side:

| Type | Best For | Material Commonality | Security Level |

|---|---|---|---|

| Vertical | Road Bikes | Aluminum/Steel | Medium |

| Horizontal | Fixed-Gear | Steel | Low-Medium |

| Semi-Vertical | Touring | Aluminum | Medium |

| Thru-Axle | MTB/Gravel | Carbon/Aluminum | High |

| Hooded/Plug | Custom | Titanium/Steel | High |

Choosing the right type depends on your riding style. For most cyclists seeking the fork dropout – no 1 in versatility, thru-axle stands out.

When we talk about fork dropout – no 1, we’re referring to designs that prioritize safety, efficiency, and longevity. High-end dropouts, like those from Paragon Machine Works or ENVE, use advanced materials to withstand extreme conditions.

Benefits include:

In a survey of cyclists, 75% reported better ride quality after upgrading their fork dropouts. If you’re building a bike from scratch, investing in a premium fork dropout – no 1 choice can elevate the entire setup.

Take a look at this close-up of a damaged dropout to understand what happens when quality is overlooked:

Selecting the fork dropout – no 1 involves considering several factors:

For electric bikes, ensure the dropout can handle added torque from motors. Always consult a bike shop for measurements.

Here’s an example of measuring dropout spacing, crucial for compatibility:

Installing or replacing a fork dropout might seem daunting, but with the right tools, it’s manageable. Note: If you’re not experienced, seek professional help to avoid voiding warranties.

For thru-axle installations, thread the axle carefully to avoid cross-threading. Videos from cycling channels demonstrate this process effectively.

View this image of a thru-axle setup during installation:

Regular maintenance keeps your fork dropout – no 1 performing at peak. Clean the area weekly to remove dirt and grime, which can cause corrosion. Lubricate moving parts sparingly, and inspect for cracks every 500 miles.

Common issues include:

By following these tips, your fork dropout can last thousands of miles.

Myth 1: All dropouts are interchangeable. Reality: Compatibility is key; mismatched sizes can damage your fork.

Myth 2: Heavier dropouts are always stronger. Reality: Modern alloys provide strength without bulk.

Myth 3: You don’t need to upgrade stock dropouts. Reality: For performance riding, a fork dropout – no 1 upgrade can make a noticeable difference.

In summary, the fork dropout – no 1 isn’t just a component—it’s the foundation of your bike’s front-end stability. Whether opting for thru-axle for off-road prowess or vertical for everyday commuting, understanding these elements empowers you as a cyclist. Invest in quality, maintain diligently, and enjoy smoother, safer rides. If you’re ready to upgrade, start by assessing your current setup and exploring options from reputable brands. Happy cycling!

| Size | One Size |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.